Manufactured Sand-SBM Industrial Technology

2020.8.26 Manufactured Sand. 2020-08-26. Summary: Natural sand is mainly formed by the impact of natural forces, but due to environmental protection and other reasons, the cost of natural sand is

consulter en ligne

Manufactured Sand - What Is It and How to Make It

2023.7.13 Manufactured sand: Rock, mine tailings or industrial waste particles with a particle size of less than 4.7mm made by mechanical crushing and screening after soil

consulter en ligne

Manufactured Sand-SBM Industrial Technology Group

2023.5.19 In this case, machine-made sand came into being and has been widely used. What are the classifications of sand? Sand can be divided into natural sand and

consulter en ligne

Manufacturing sand - Metso

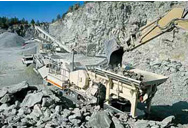

Manufactured sand is a viable alternative for natural sand. It is a way to preserve natural river banks and shorelines where sand would otherwise be extracted. Solutions for

consulter en ligne

Particle Characterization of Manufactured Sand and Its

2022.6.30 Shen et al. studied the particle shape and surface roughness of river sand and eight kinds of manufactured sand with DIP technology and found that manufactured

consulter en ligne

Production of Manufactured Sand SpringerLink

2022.10.4 Currently, there are mainly two types of sand washers in the market: wheel sand washers and spiral sand washers. The particle grading of MS is reasonable, and

consulter en ligne

Manufactured sand for the development of reinforced

2022.1.1 Manufactured sand known as M sand is common and it is used as fines in the development of concrete composites [3]. They are produced artificially by crushing

consulter en ligne

Manufactured Sand Agg-Net

2008.6.2 Manufactured Sand. 02 June, 2008. An effective dry sand manufacturing process from Japan. By Hugo Pettingell. There is little doubt that viable natural sand resources in many areas around the world are

consulter en ligne

A promising future for manufactured sand Aggregates

2017.11.9 Reduced access to dwindling natural sand sites, coupled with higher quality sand products produced by crushing rock with premium crushing and screening

consulter en ligne

Manufacturing Sand Agg-Net

2012.9.17 Manufactured sand ranges from unprocessed quarry dust to carefully processed fine aggregate specifically designed for use in concrete. It may be gritty, flaky and full of filler or well shaped and

consulter en ligne

Study on the Strength and Microcosmic Characteristics

2022.10.19 Manufactured sand. (a) Excavated tunnel; (b) Manufactured sand. There are several advantages of using superfine powders, such as fly ash (FA) [11,12 ], silica fume (SF) [13 –15], and red mud powder (RM) [16] as the admixtures to fill the man-ufactured sand gap. First, themobility of fresh concrete will be improved because these

consulter en ligne

Manufactured sand for the development of reinforced

2022.1.1 Manufactured sand known as M sand is common and it is used as fines in the development of concrete composites [3]. They are produced artificially by crushing hard granite stones into smaller grains and it is washed to remove minute particles and graded as fine aggregate. M sand particles are mostly angular and rough in texture and preferred in ...

consulter en ligne

Research on the particle characteristics of manufactured sands ...

2023.6.13 The density of the manufactured sand used in this study is slightly higher than that of the natural sand, where the density of the former is 2680 kg/m 3 and that of the latter is 2660 kg/m 3. The corresponding volume fractions of the sand can be calculated according to the mass ratio of the sand in Table 2. At the water-cement ratio of 0.42 ...

consulter en ligne

Trace and major minerals of (natural and manufactured) sand

2021.1.12 The mineralogical characterization suggested that the grain size separation is meaningless for manufactured sand, and quartz is a major mineral for river sand (the Extinction coefficient ranges from 3.86–234). Content of magnetic minerals for manufactured sand (mean [s.d.] value of χ = 736 [386] × 10–8 m3 kg−1) is higher than for river ...

consulter en ligne

Particle Characterization of Manufactured Sand and Its

2022.6.30 The maximum angularity values of MSA—MSE are 41.52%, 61.01%, 84.25%, 5.82%, and 21.18% higher than the minimum angularity values, respectively. This shows that MSC has the largest fluctuation of angularity, while MSD has the most stable fluctuation of angularity among the five kinds of manufactured sand.

consulter en ligne

Durability of manufactured sand concrete in atmospheric

2022.12.1 After 45 days, the mass of manufactured sand decreases more gently. That is the loss of dissolution mass is lower compared with river sand concrete combined with Section 3.2.1, which reflects that the manufactured sand concrete are more dense. There is a sharp drop in the mass of the MS specimens after 75 days.

consulter en ligne

A mix proportion design method of manufactured sand concrete based

2013.7.1 Manufactured sand is considered suitable for use in concrete if the multiple of the MBV and the passing 75-μm size of the sample is 150 or less [17]. The MBV is not related with the limestone dust content of MS, but in direct proportion to clay content. When the MBV is less than or equal to 1.35, the change of the MBV has a little influence on ...

consulter en ligne

Effect of Stone Powder Content on Mechanical Properties of Manufactured ...

2022.5.11 The stone powder content of manufactured sand is generally as high as 10–20%. Compared with natural sand, manufactured sand has the characteristics of irregular grain shape, unreasonable gradation, and high stone powder content (Wang et al. 2018; Zheng et al. 2021), which limits the popularization and application of manufactured

consulter en ligne

Abstract

2021.1.20 The mechanical properties of manufactured sand concrete are related to the physical properties of fine aggregate with different lithologies. With the increase of fineness modulus or stone powder content, the peak stress and peak strain of manufactured sand concrete show a trend of first increasing and then decreasing.

consulter en ligne

Particle Characterization of Manufactured Sand and Its

2.1. Raw Materials. Portland cement was obtained from Cement Company of Guangxi Yufeng. Its characteristics were tested according to GBT1346-2011, and the results are shown in Table 1.Fly ash was obtained from Qingshan Thermal Power Factory, and stone powder was the coproduct of Manufactured Sand A (MSA), which was obtained from

consulter en ligne

Performance evaluation of cement mortar produced with manufactured sand ...

2021.8.23 When manufactured sand in mortar content was 25% and 50%, the water retentivity was significantly improved than other replacements and control mixes. Mortars at lower replacements greatly advanced the flexural strength, compressive strength and capillary water absorption. Linear shrinkage and thermal expansion of mortars were also

consulter en ligne

Increasing sustainable aggregate usage in concrete by

2022.2.28 1. Introduction. The use of manufactured sands, a man-made fine aggregate product from crusher fines, as a partial replacement or 100% replacement of fine aggregate in a concrete mixture has become more common [16], [20], [21].Manufactured sands are essentially a waste product from producing coarse aggregate and so it is

consulter en ligne

(PDF) EFFECT OF MANUFACTURED SAND AS A REPLACEMENT

2018.10.9 Moreover, the replacement percentage increases the percentage difference up to 3.38%, 3.76% and 11.86%, respectively than natural sand strength (13) . In (15) studied, Msand (30% and 50% ...

consulter en ligne

Particle Characterization of Manufactured Sand and Its

2022.6.30 With the rapid development of infrastructure construction, it is an inevitable trend to replace natural sand in short supply with manufactured sand to meet sustainable development. In this paper, the relationship between the particle shape characteristics of manufactured sand and concrete performance is discussed using a morphological

consulter en ligne

Surface post-treatments for metal additive ... - ScienceDirect

2021.1.1 Sand/bead blasting (SB) is the operation of propelling abrasive material such as sand or ceramic beads against the target surface under high pressure. This treatment is commonly used in multiple industrial sectors to smoothen the surface roughness, shape form thin structures or remove surface oxides or contaminants.

consulter en ligne

Manufactured Sand - दृष्टि आईएएस

2023.1.28 Consistency: Manufactured sand can have a consistent grain size and shape, which can be beneficial for construction projects that require a specific type of sand. Environmental Benefits: Using manufactured sand can help to reduce the need for mining natural sand, which can have negative environmental impacts. Additionally, using the

consulter en ligne

Rheological and mechanical properties of mortars

2008.10.1 The conventional assessment methods for fine aggregate used in Portland cement concrete are mostly based on round natural sand performance in spite of the increasing use of angular manufactured sands. Two natural and two manufactured sands were selected and tested at different water–cement ratios and fine aggregate-to-cement

consulter en ligne

Research on the influence of manufactured sand

manufactured sand produced in a gravel mill in Anhui Province. Two types of manufactured sand are selected: 7 types of manufactured sand with different fineness modulus in the actual production process, and the grain composition is shown in Table 1. The grain composition of manufactured sand is adjusted according to the

consulter en ligne

The benefits of using manufactured sand with cement for

2020.5.12 To understand the chemical mechanisms in the stabilisation process, X-ray fluorescence test (XRF), XRD and SEM were applied to examine the composition and microstructure of peat and the manufactured sand, with results shown in Table 3, Figs. 4 and 5.It can be seen from Table 3, apart from the organic matter, silicon (SiO 2) and

consulter en ligne

- liste de mhada de l usine de porcelaine sewree

- sable faire rocher inde

- cours traitement de minerai de lor

- pierre cours de broyage de l

- acheter de l'acier broyeur à boulets Afrique

- mps roller mill chargement rod

- la separation par gravite de grenat

- broyeur à boulets conception complète

- attachement de la râpe de noix de coco

- conception de concasseur à cone liming

- chema de traitement de minerai

- broyeur de pierre crhser à vendre

- calcul de la capacité de conception du broyeur à boulets

- coût pour installer une machine en pierre

- lames de broyage pour usines de plomb